A-A-2670A

2. SALIENT CHARACTERISTICS

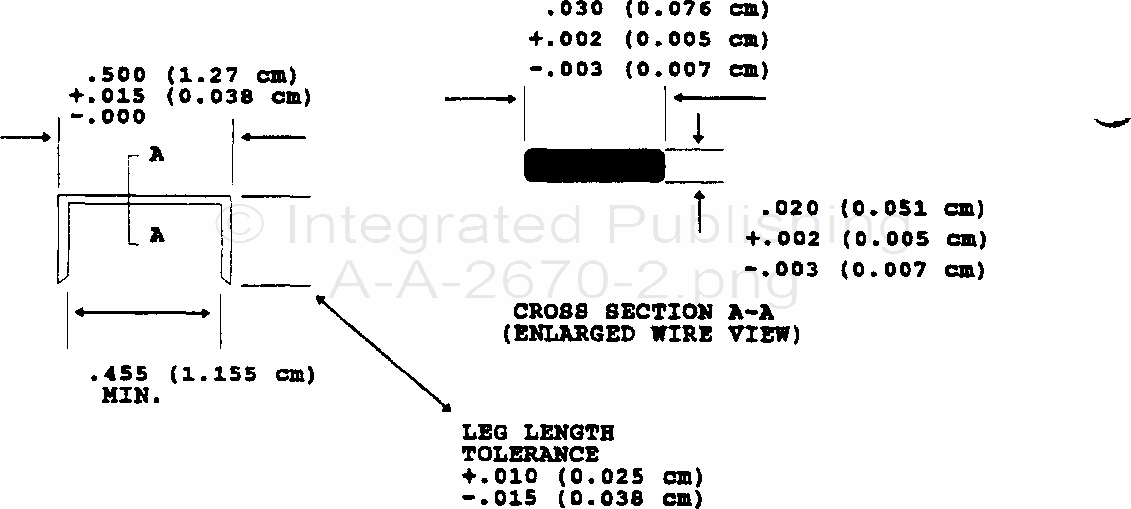

2.1 Type I staples. Type I, medium duty staples shall be in accordance with the dimensions shown in figure 1. The staples shall be preformed to a U-shape, conforming to figure 1. The staples shall be cemented together in strip form, each strip consisting of a minimum of 137 staples and a maximum strip length of 4.48 inches (11.38 cm).

The number of staples per strip in box (see 5.1) shall average 140. The cement shall be applied smoothly and shall be set in such a manner that the surfaces of the strips shall be free from thickness. The cemented staple strip shall easily slide through the tacker (see 2.3). The staple points or ends shall be of such design that the staples will meet the test in section 4. The steel wire shall be so tempered as to provide penetration of the staple to a firm seat without buckling or fracturing. The leg length(s) of the staples shall be in accordance with the sizes (s) specified. The staples shall be tinned, galvanized, or made equally corrosion resistant.

2.2 Type II staples. Type II, heavy duty staples shall be in accordance

with paragraph 3.1, except that the staples shall be in accordance with the

dimensions shown in figure 2, and shall be cemented together in strips

consisting of a minimum of 82 staples and a maximum strip length of 4.37 inches

(11.1 cm). The number of staples per strip in each box (see 5.2) shall average

84.

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business